3003 aluminium e kopantsoeng ka tube

3003 e Bolela'ng ka Coil ea Aluminium?

Linomoro tse ka har'a khoele ea aluminium ke khoutu ea alloy, e u bolellang hore na ke likarolo life tse ka har'a motsoako.Nomoro ea pele e bua ka motsoako oa eona oa bohlokoa ka ho fetisisa.Nomoro ea bobeli e bontša phapang ea alloy (haeba e fapane le zero), 'me nomoro ea boraro le ea bone e khetholla letoto la eona.

Bakeng sa khoele ea aluminium ea 3003, nomoro ea pele '3' e bolela hore ke motsoako oa manganese, '0' e bolela hore ha e na phapang, 'me linomoro tsa ho qetela '03' li bolela hore e tsoa ho lihlopha tse 3000.Sekema sena sa dinomoro se itshetlehile hodima Sisteme ya Matjhaba ya Tlhophiso ya Alloy.

Thepa ea 3003 Alloy Aluminium Coil

3003 aluminium coil e na le moeli oa lik'hemik'hale oa silicon ea 0.6, 0.7 tšepe, 0.05-0.20 koporo, 1-1.5 manganese, 0.10 zinc, le 0.15 ho tsoa linthong tse ling.

Aluminium ea 3003 e na le matla a ho fihla ho 200MPa, 'me mekhoa eohle e ka e cheseletsa habonolo.E mamella ho bola libakeng tse ngata ntle le ha e le metsing a leoatle kapa libakeng tse ling tse senyang tse nang le chlorine kapa fluorine.

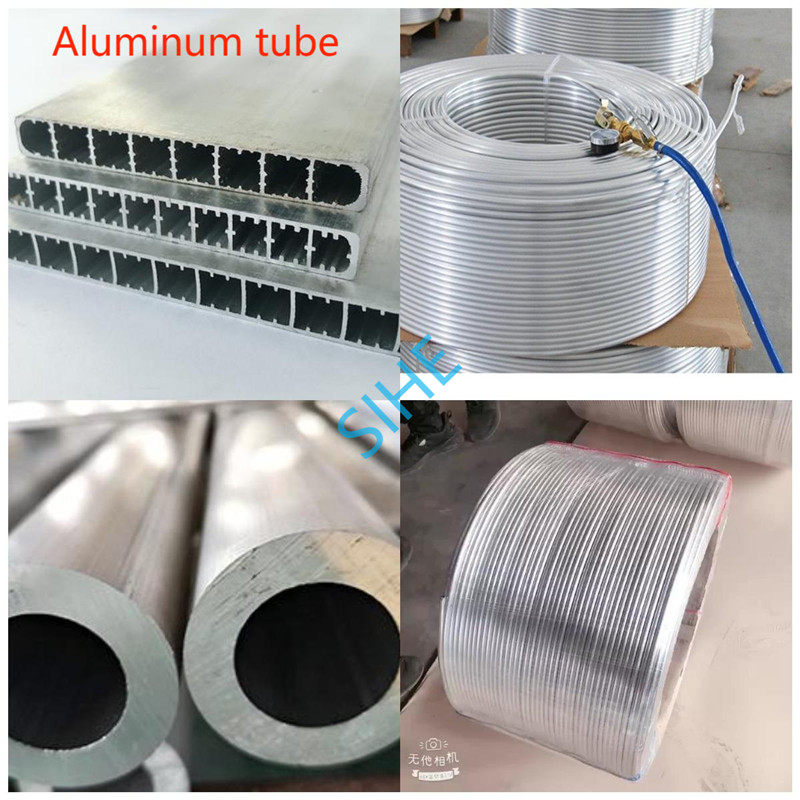

Likhoele tsa 3003 tsa alloy aluminium li tla ka libopeho le boholo bo fapaneng - ho tloha maqepheng a botenya ba limilimithara tse 0.4 ho isa ho li-tubes tse botenya ba 12 mm.Ho na le likhetho tse ngata ha u etsa qeto ea lisebelisoa bakeng sa projeke ka 'ngoe.Li fumaneha hape ka likhoele (bakeng sa ts'ebeliso ea indasteri) le bolelele bo otlolohileng (bakeng sa merero ea khoebo).

3003 Aluminium Coil Vs.3004 Aluminium Coil

3003 aluminium coil le 3004 aluminium coil ka bobeli li sebelisoa mefuteng e mengata ea lits'ebetso.Le hoja li tšoana, ha li tšoane, 'me e' ngoe le e 'ngoe e na le melemo le mathata a eona.

Li-alloys tsa 3003 le 3004 li tšoana ka ho hlophisoa, empa 3004 e na le magnesium e eketsehileng ea 1%, e etsang hore e be matla hanyenyane.Sena se fella ka khanyetso e ntle ea kutu ha e pepesehile tikolohong ea asiti, e leng se etsang hore motsoako ona o theko e boima haholo ho o hlahisa ho feta li-alloys tsa 3003.

The 3003 aluminium alloy e fana ka ductility e betere ho feta 3004 alloy le weldability ka lebaka la litaba tsa eona tse tlase tsa magnesium;leha ho le joalo, e na le karo-karolelano e tlase ea matla ho boima ho feta thepa ea morao-rao ka lebaka la boima ba eona bo tlase.

Mabapi le ts'ebeliso ea tikoloho, 3003 e ka phekoloa mocheso le ho sebetsa ha serame, empa 3004 e ka sebetsa feela ka serame.

Litlhaloso

| Alloy Che. | Khalefo | Straight Tube | LWC | ||

| OD(mm) | WT(mm) | OD(mm) | WT | ||

| 1060(L2) | R(H112) | 6-30 | 0.6-3 | 4 ~ 22 | 0.2~2 |

| M(O) | 6-30 | 0.6-3 | 4 ~ 22 | 0.2~2 | |

| H 14 | 6-30 | 0.6-3 | 4 ~ 22 | 0.2~2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6-30 | 0.6-3 | 4 ~ 22 | 0.2~2 |

| H12 | 6-30 | 0.6-3 | 4 ~ 22 | 0.2~2 | |

| H14 | 6-30 | 0.6-3 | 4 ~ 22 | 0.2~2 | |

| H18 | 6-30 | 0.6-3 | 4 ~ 22 | 0.2~2 | |

| 6063 (LD31) | M(O) | 6-30 | 0.6-3 | 4 ~ 22 | 0.5~2 |

| T4 | 6-30 | 0.6-3 | 4 ~ 22 | 0.5~2 | |

| T6 | 6-30 | 0.6-3 | 4 ~ 22 | 0.5~2 | |

Tlhaloso ea Inner Groove Aluminium Tube (Boholo bo ka etsoa ka mokhoa o ikhethileng)

| Tlhaloso(mm) | Botenya ba lebota(mm) | Grooved Height(mm) | Helical angle(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0,55 | 0.05-0.18 | 18 |

Thepa ea Mechini ea Inner Aluminium Grooved Tube

| Lintho tse bonahalang | Tensile | Elongation Rate | Ho Atolosa Sekhahla |

| 3003 | 130MPA | 35 | 40 |

Tlhaloso ea Coil ea Pakete

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Botenya ba Lerako | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

Quanlity Gurantee

| A1050 Aluminium Chemical Sebopeho | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Ba bang |

| 99.5-100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical Sebopeho | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Ba bang |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical Sebopeho | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Ba bang |

| 99.7-100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium Chemical Sebopeho | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Ba bang ha ba Soha | |

| ba bang | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0 ~ 1.5 | 0~0.70 | 0~0.05 | |

| Alloy | Khalefo | Tlhaloso | |||

| Botenya(mm) | Diameter(mm) | Matla a tšepe | Ho thatafala | ||

| 7075 7005(tube) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063(profile) | T5,T6 | >1.6 | 10-180 | > 572 Mpa | HB90-110 |

| Bolelele: <6Meter | |||||

| MOHALE | BOTETE(mm) | MATLA A TŠEPE | ELONGATION% | Standard |

| T5 | 0.4-5 | 60-100 | ≥20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥4 | |

| T9 | 0.5-6 | 85-120 | ≥2 |

Sehlahisoa sa Aluminium