Alloy 600 Stainless Steel Coil Tubing Price

Sebopeho sa Lik'hemik'hale,%

Likopo tse tloaelehileng tsa kutu li kenyelletsa tlhahiso ea titanium dioxide (tsela ea chloride), li-perchlorethylene syntheses, vinyl chloride monomer (VCM), le magnesium chloride.Alloy 600 e sebelisoa ho hlahisa le ho boloka lik'hemik'hale le lijo, ho phekola mocheso, phenol condensers, tlhahiso ea sesepa, lijana tsa meroho le mafura a mafura le tse ling tse ngata.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 mets | 14.0-17.0 | 6.0-10.0 | .15 max | 1.00 max | .015 boholo | .50 max | .50 max |

Inconel 600 e sebelisoa lits'ebetsong life?

- Indasteri ea lik'hemik'hale

- Sepakapaka

- Indasteri ea ho phekola mocheso

- Indasteri ea pampiri le pampiri

- Ho lokisa lijo

- Boenjiniere ba Nyutlelie

- Likarolo tsa turbine ea khase

Litlhaloso tsa ASTM

| Pipe Smls | Pipe Welded | Tube Smls | Tube e Welded | Leqephe/Letlapa | Sebaka | Ho qapa | E loketseng | Mohala |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Thepa ea Mechini

Mocheso o tloaelehileng oa kamore Tensile Properties of Annealed Material

| Foromo ea Sehlahisoa | Boemo | Tensile (ksi) | .2% Tlhahiso (ksi) | Elongation (%) | Ho thatafala (HRB) |

| Rod & Bar | Mohatsela-qhoa | 80-100 | 25-50 | 35-55 | 65-85 |

| Rod & Bar | Ho Qetsitsoe | 80-100 | 30-50 | 35-55 | 65-85 |

| Tube & Pipe | Ho Qetsitsoe | 75-100 | 25-50 | 35*55 | - |

| Tube & Pipe | Mohatsela-qhoa | 80-100 | 25-50 | 35-55 | 88 mak |

| Letlapa | E chesehang | 80-105 | 30-50 | 35-55 | 65-85 |

| Leqephe | Mohatsela-qhoa | 80-100 | 30-45 | 35-55 | 88 mak |

Inconel 600 Melting Point

| Element | Botenya | Melting Point | Matla a tšepe | Matla a Hlahisa (0.2%Offset) | Elongation |

| Alloy 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi - 95,000 , MPa - 655 | Psi - 45,000 , MPa - 310 | 40% |

Inconel 600 E lekanang

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | BS | GOST | HLOMPHO | EN |

| Alloy 600 | 2.4816 | N06600 | NCF600 | NNA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

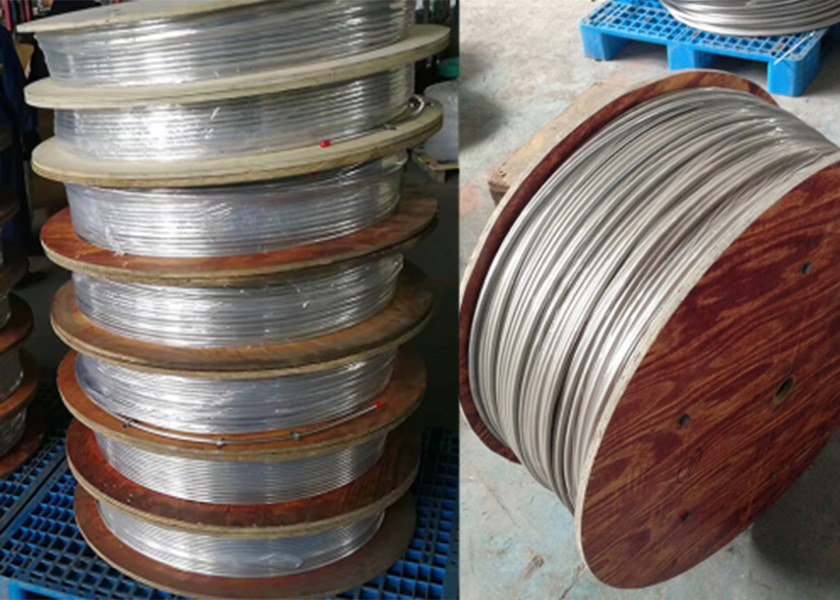

Alloy 600 Tubing

Alloy 600 ke mokhethoa ea hloahloa bakeng sa litšebeliso tse ngata mochesong o phahameng haholo le tikolohong e senyang haholo.Motsoako oa nickel le chromium o fana ka khanyetso e tiileng ho oxidation mochesong o sebetsang.Lithempereichara tsena li ka fapana ho tloha ho cryogenic ho isa ho tse 2,000 tsa F.Lintho tse phahameng tsa nickel tsa alloy 400 li boetse li fana ka ho hanyetsa hoo e batlang e le ho feletseng khahlanong le khatello ea maikutlo ea ho senya, e atisang ho fumanoa libakeng tsa chloride.

Ho bohlokoa ho hlokomela hore karolo ea chromium ea profil ea lik'hemik'hale ea alloy e etsa hore ho khonehe hore kereiti e khone ho mamella mocheso o phahameng.Sebopeho se setle sa lijo-thollo tsa tube e phethiloeng e batang, ho feta moo, e tlisa khanyetso e ntle ea kutu, e kenyelletsang mokhathala o phahameng le boleng ba matla a tšusumetso.

Litlhaloso tsa Sehlahisoa

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Boholo Range

| Kantle ho Diameter (OD) | Botenya ba Lerako |

| .250”–.750” | .035”–.083” |

Litlhoko tsa Lik'hemik'hale

Alloy 600 (UNS N06600)

Moetso %

| Ni Nickel | Cu Koporo | Fe Tšepe | Mn Manganese | C Khabone | Si Silicone | S Sebabole | Cr Chromium |

| 72.0 mets | 0.50 max | 6.00–10.00 | 1.00 max | 0.15 max | 0.50 max | 0.015 boholo | 14.0–17.0 |

Dimensional Tolerances

| OD | OD Mamello | Mamello ea Lerako |

| ≤ .500” ntle le | +.005” | ± 12.5% |

| .500”–.750” ntle le | +.005” | ± 12.5% |

Thepa ea Mechini

| Kotulo e Matla: | 35 ksi mets |

| Matla a tšepe: | 80 ksi mets |

| Elongation (metsotso 2"): | 30% |

Boqapi

Alloy 600 e ka tšeloa habonolo ka mokhoa o tloaelehileng.Tsamaiso ea motsoako ona e ntle haholo, e lutseng pakeng tsa ts'ebeliso ea T303 le T304.

Lifoto tsa fektheri

Tlhahlobo

Thomello & Paka

Tlaleho ea Tlhahlobo