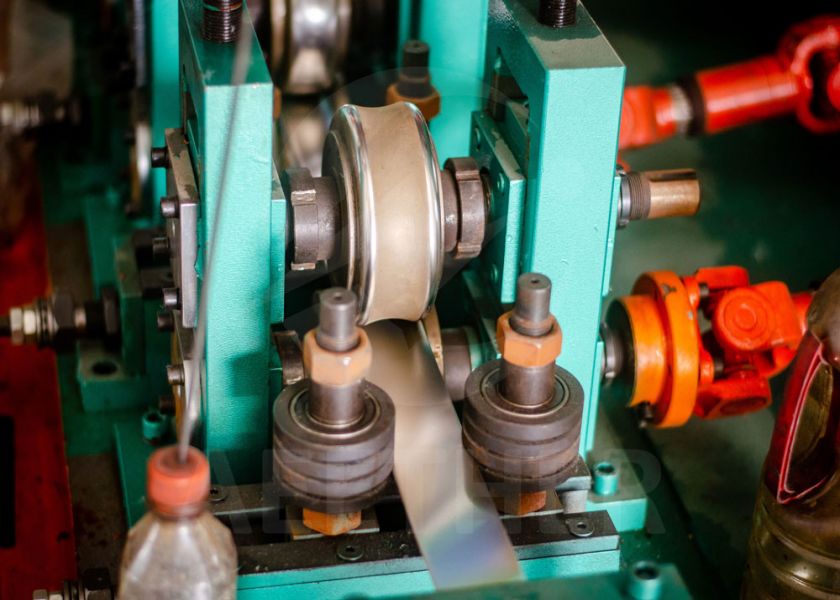

321 tšepe e sa hloekang 5 * 1.2mm capillary tubing

Alloy 321 (UNS S32100) ke a

titanium e tsitsitse austenitic

tšepe e se nang mochini e nang le kakaretso e ntle

khanyetso ea kutu.E na le bokhabane

ho hanyetsa ho bola ha intergranular

ka mor'a ho pepesehela mocheso ho

chromium carbide pula

321 tšepe e sa hloekang 5 * 1.2mm capillary tubing

sebaka sa 800–1500°F (427–816°C).

Motsoako o hanana le oxidation ho 1500°F

(816 ° C) 'me e na le meea e holimo le

khatello ea maikutlo ho felloa ke li-alloys

304 le 304L.E boetse e ruile

boima bo botle ba mocheso o tlase.

Alloy 321H (UNS S32109) ke eona

khabone e phahameng (0.04–0.10) phetolelo ea

motsoako.E ile ea ntlafatsoa bakeng sa

matlafatsoa khanyetso le bakeng sa

matla a phahameng mochesong

ka holimo ho 1000°F (537°C).Ka bongata

mehlala, dikahare tsa carbon tsa

plate e nolofalletsa setifikeiti tse peli.

Alloy 321 e ke ke ea thatafatsoa ke

phekolo ea mocheso, feela ka ho sebetsa ho batang.

Ho ka ba bonolo welded le

e sebetswa ke lebenkele le tlwaelehileng

mekhoa ea ho etsa lintho.

Lisebelisoa

• Sepakapaka

- enjene ea piston

mefuta e mengata

• Tšebeliso ea Lik'hemik'hale

• Manonyeletso a Katoloso

• Phetoho ea Lijo—lisebelisoa

le polokelo

• Petroleum Refining—polythionic

tšebeletso ea acid

• Phekolo ea litšila-e chesang

li-oxidizers

Litekanyetso

321 tšepe e sa hloekang 5 * 1.2mm capillary tubing

ASTM ……………….. A 240

ASME ……………….. SA 240

AMS …………………….5510

Tlhahlobo ea Lik'hemik'hale

Weight % (litheko tsohle li holimo ntle le haeba ho boletsoe ka tsela e 'ngoe)

Leqephe la lintlha: Alloy 321/321H

(UNS S32100, S32109) W. Nr.1.4541

Titanium Stabilized Austenitic Stainless Steel e nang le khanyetso e ntle haholo

ho Intergranular Corrosion Ka mor'a ho Peheloa ke Lithempereichara ka

Chromium Carbide Pula Range ya 800–1500°F (427–816°C)

321 tšepe e sa hloekang 5 * 1.2mm capillary tubing

Alloy 321 06/2014

rev 02/2023 PDF link

Lintho Tsa 'Mele

Botenya

0.286 lbs /in3

7.920 g/cm3

Modulus ea Elasticity

28.0 x 106 psi

193 GPA

Melting Range

2550–2635°F

1398–1446°C

Mocheso o khethehileng

0.12 BTU/lb-°F (32–212°F)

500 J/kg-°K (0–100°C)

Thermal Conductivity 212°F (100°C)

9.3 BTU/hr/ ft2/ft /°F

16.0 W/m-°K

Ho hanyetsa Motlakase

72 Microhm-cm ho 20°C

Thepa ea Mechini

Maemo a Tlwaelehileng ho 68°F (20°C)

Mocheso Range

°F

°C

ka/ka °F

cm/cm °C

68–212

20–100

9.2 x 10-6

16.0 x 10-6

68–1112

20–600

10.5 x 10-6

18.9 x 10-6

68–1832

20–1000

11.4 x 10-6

20.5 x 10-6

Kotulo Matla

Ultimate Tensile

Elongation

Ho thatafala

0.2% Offset

Matla

ka 2in.

psi (mets.)

(MPa)

psi (mets.)

(MPa)

% (mets.)

(max.)

30,000

205

75,000

515

40

217 Brinell

Ngola molaetsa wa hao mona mme o re romele wona