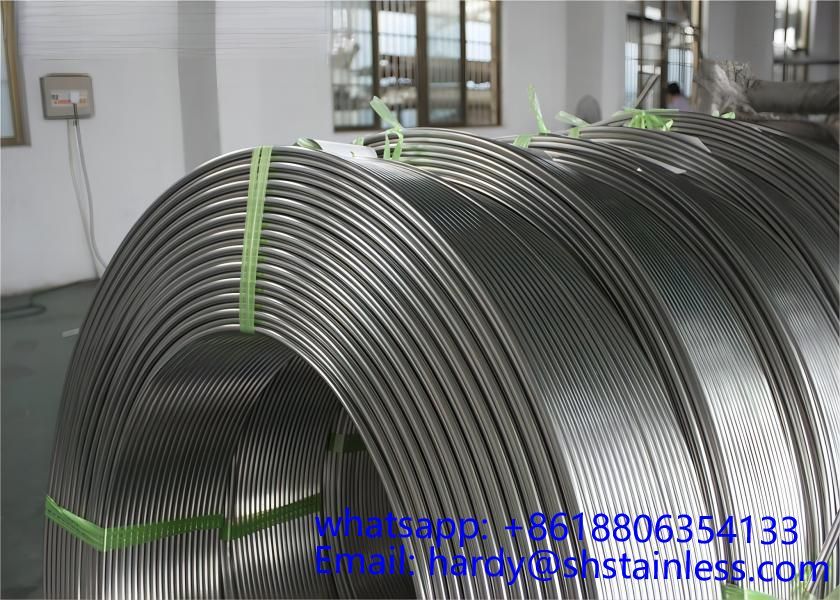

321L tšepe e sa hloekang 8 * 1mm e kopantsoeng tubing

321 Tšepe e Hloekileng

Leqephe lena la data le sebetsa ho tšepe e sa hloekang ea 321 / 1.4541 e chesang le e batang e phuthoang le ho hlobolisa, lihlahisoa tse feliloeng, mekoallo, terata e phuthoang le li-profiles hammoho le li-tubes tse se nang moroallo le tse cheselitsoeng molemong oa khatello.

321L tšepe e sa hloekang 8 * 1mm e kopantsoeng tubing

1.4541

Kopo

Lisebelisoa le likarolo tsa kaho indastering ea lijo, lijo tse mabothobotho, indasteri ea lifilimi le lifoto hammoho le lingoliloeng tse sebelisoang letsatsi le letsatsi ka tlung, kaho ea seteishene sa motlakase.Ka lebaka la Ti-alloy, ho hanyetsa ho bola ha intergranular ho boetse ho tiisetsoa ka boemo ba welded.

321L tšepe e sa hloekang 8 * 1mm e kopantsoeng tubing

Mefuta ea Lik'hemik'hale

| Element | % E teng (ka sebopeho sa sehlahisoa) | |||

|---|---|---|---|---|

| C, H, P | L | TW | TS | |

| Khabone (C) | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.08 |

| Silicon (Si) | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 |

| Manganese (Mn) | ≤2.00 | ≤2.00 | ≤2.00 | ≤2.00 |

| Phosphorous (P) | ≤0.045 | ≤0.045 | ≤0.0453) | ≤0.040 |

| Sebabole (S) | ≤0.0151) | ≤0.0301) | ≤0.0153) | ≤0.0151) |

| Chromium (Cr) | 17.00 - 19.00 | 17.00 - 19.00 | 17.00 - 19.00 | 17.00 - 19.00 |

| Nickel (Ni) | 9.00 - 12.00 | 9.00 - 12.002) | 9.00 - 12.00 | 9.00 - 12.002) |

| Titanium (Ti) | 5xC ho isa ho 0.70 | 5xC ho isa ho 0.70 | 5xC ho isa ho 0.70 | 5xC ho isa ho 0.70 |

| Tshipi (Fe) | Ho leka-lekanya | Ho leka-lekanya | Ho leka-lekanya | Ho leka-lekanya |

321L tšepe e sa hloekang 8 * 1mm e kopantsoeng tubing

Mechanical properties (mocheso oa kamore ka boemo ba annealed)

| Foromo ea Sehlahisoa | Botenya bo Phahameng (mm) | Kotulo Matla | Matla a tšepe | Elongation min.ka % | Matla a Impact (ISO-V) ≥ 10mm e teteaneng | |||

|---|---|---|---|---|---|---|---|---|

| 0.2% Rp0.2 N/mm2 | 1% Rp1.0 N/mm2 | Rm N/mm2 | A1) %mts (longitudinal) | A1) %min (karolelano) | Jmin (longitudinal) | Jmin (karolano) | ||

| C | 8 | 2203) | 2203) | 520-7203) | - | 40 | - | - |

| H | 13.5 | 2003) | 2403) | 520-7203) | - | 40 | 100 | 60 |

| P | 75 | 2003) | 2403) | 500-7003) | - | 40 | 100 | 60 |

| L | 160 | 1904) | 2254) | 500-7004) | 40 | - | 100 | - |

| L | 2502) | 1907) | 2257) | 500-7007) | - | 30 | - | 60 |

| TW | 60 | 1805) | 2155) | 460-6805) | 35 | 30 | 100 | 60 |

| TS | 60 | 1805) | 2155) | 460-6805) | 35 | 30 | 100 | 60 |

321L tšepe e sa hloekang 8 * 1mm e kopantsoeng tubing

Lintlha tsa litšupiso mabapi le likarolo tse ling tsa 'mele

| Boima ba 20°C kg/m3 | 7.9 | |

|---|---|---|

| Modulus of Elasticity kN/mm2 ho | 20°C | 200 |

| 200°C | 186 | |

| 400°C | 172 | |

| 500°C | 165 | |

| Thermal Conductivity W/m K ho 20°C | 15 | |

| Mocheso o Khethehileng oa 20°CJ/kg K | 500 | |

| Ho hanyetsa Motlakase ho 20°C Ω mm2 /m | 0.73 | |

321L tšepe e sa hloekang 8 * 1mm e kopantsoeng tubing

Coefficient of linear thermal extension 10-6 K-1 pakeng tsa 20°C le

| 100°C | 16.0 |

|---|---|

| 200°C | 16.5 |

| 300°C | 17.0 |

| 400°C | 17.5 |

| 500°C | 18.0 |

Ngola molaetsa wa hao mona mme o re romele wona